|

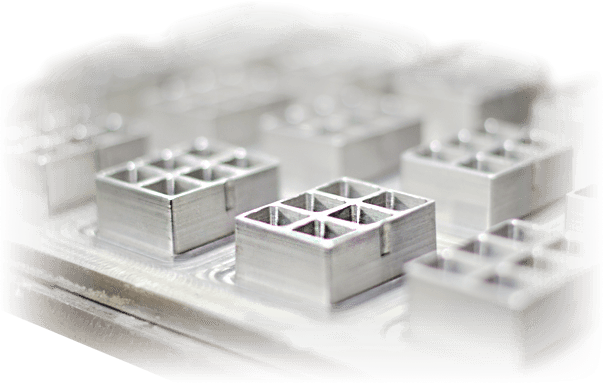

| Mold Design |

| |

PFI can help you make your idea a reality with our design, engineering, and production capabilities. The following stages explain the process that can bring your idea to LIFE. |

| |

|

You relate your idea in an informal meeting, phone conversation, or email. With this information, we can tell you if our expertise can help you. Next, we discuss scheduling, projected volume, product design, and use. Preliminary decisions about material, caliper, color, and texture can be made at this stage. |

|

Once we understand your needs through the consultation we can establish which facets of the project PFI can assume responsibility of. Numerous quotation options will then be calculated to help decide how best to meet your needs. |

|

Drawings, models, or prototype parts may be prepared for your evaluation. A prototype program can be conducted at a fast turnaround using our in-house capabilities. |

|

| Customer Involvement |

PFI staff members know that product development is a team effort from beginning to end. A full-time research and development team are the first to become involved in any project.

In house mold design and manufacturing reduces cost for toll production. Our primary goal is to work closely with our customer's staff . PFI recognizes that clients often know what they want and have valuable input about the most important aspects of a project. That information may come from your engineering, manufacturing, marketing or purchasing departments.

The early phases of a project are kept open to include as many ideas as are offered. This way, PFI's design and engineering personnel will be able to consider the widest range of possible options when determining the best thermoforming solution.

At PFI, we mean it when we say that our company is " Where your packaging ideas take form." And it's done at a price meant to keep your product and your profit protected.

|

|

| Job Initiation |

Your packaging design can be initiated by simply sending a print of your product or you may send a sample of the product to be packaged. PFI will communicate with you right away in person, via teleconferencing, faxing or by e-mail to clarify what your requirements are and to incorporate your staff's ideas. |

| Formability Requirements |

The next stage involves determining the formability requirements. Our design team fully explores the best material, or materials, for your packaging project. For example, if your product moves directly to the consumer or a retail setting, this will have an effect upon which materials are reviewed. If your product is a part which must be transferred internally or shipped from one supplier to another, that too brings into play other variables to consider. PFI can form all types of materials, ranging in gauge from .0075" through .250" starting thickness. We can form a single sheet up to and including a size of 48" x 48". |

|

|

|

|